Chemicals Management

UCPC has promoted several concepts aimed at sustainable chemicals management at industrial level. Taking a proactive sustainable chemistry approach supports risk management of chemicals, materials and products from their conception and enhances life-cycle thinking. Some of the Projects undertaken by UCPC to promote sustainable chemicals management include;

- Chemical leasing

- Green chemistry

- Innovative Approaches for the sound management of chemicals and chemical waste.

Global Green Chemistry Innovation and Network Programme

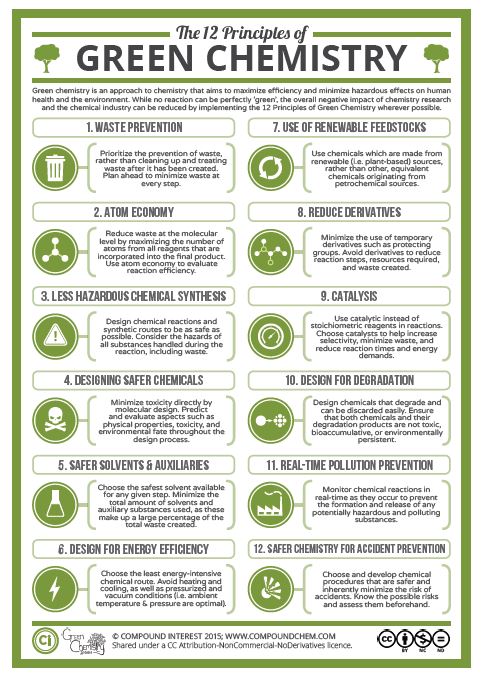

Green chemistry is the design of chemical products and processes to reduce or eliminate the generation and use of hazardous substances.

In Uganda, substances containing C6-perfluorinated compounds are commonly used as liquid repellants in textiles and in insulation in electrical cables. For example; One textile industry in Uganda uses about 6tons/y of C6-perfluorinated compounds in production of about 187.78tons/y of fabric. Other water resistant materials including laminated polypropylene material and TYVEK are used as raw materials in production of medical gowns.

Use of these substances is often associated with release of Perfluorohexanesulphonic acid (PFHxS) and PFOA, which are persistent in environment, very resistant to chemical, thermal and biological degradation and have influence on the nervous system, brain development, endocrine system and thyroid hormone.

Through funding from Global Environment Facility (GEF), United Nations Industrial Development Organisation (UNIDO) which is the implementing agency in conjunction with Yale University as the executing agency are partnering with Uganda Cleaner Production Centre and other Research institutions, government agencies and NGOs to implement the project “Global GreenChem Innovation and Network Programme (GGCINP)” with the aim of scaling up green chemistry for POPs and mercury replacement through capacity building and innovation, and creation of a global unifying green chemistry network for implementation and uptake.

Chemical Leasing (ChL)

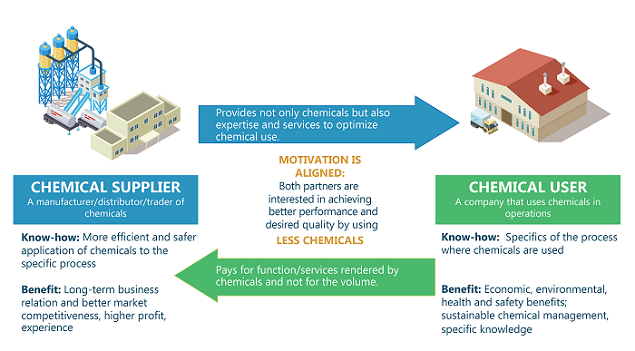

Uganda Cleaner Production Centre with support from United Nations Industrial Development Program implemented the Chemical Leasing project. The unsustainable management of chemicals in industries and lack of cooperation among chemicals producers and users led to this project. Chemical Leasing (ChL), based on the preventive Resource Efficient and Cleaner Production (RECP) concept, provides practical solutions for industry to become more efficient and at the same time reduce unnecessary hazardous chemicals consumption and protect human health and the environment. Chemical Leasing is thus in line with the UNIDO Green Industry approach which strives for decoupling resource use and pollution from industrial development and promoting the growth of productive sectors in developing and transition countries.

Chemical Leasing is a preventive and service-oriented business model that shifts away from high sales volumes of chemicals towards an integrated approach and extended producer responsibility throughout the entire life cycle of a chemical. Unlike traditional business models, ChL is based on a value-oriented (for the function of the chemical) instead of a volume-based pricing (for the amount of the chemical). By de-coupling the payment from the consumption of chemicals, ChL encourages better chemicals management. This results in clear environmental advantages as well as consequent economic benefits for both suppliers and users of chemicals.

UCPC conducted two national ChL awareness-raising workshops with 44 participants from industries, Academia and Research organizations. Three chemical suppliers and 15 industries were been visited various times to promote the concept of ChL. UCPC managed to secure one ChL contract signature for the implementation of three Chemical Leasing projects in Crown beverages Limited with Diversey Eastern and Central Africa Ltd being the service provider.

The implemented projects include; Conveyor lubrication processes on all glass lines, Caustic detergent services on all bottle washers and case washers on all glass bottling lines and Final rinse additive application services on the bottle washers. This implemented ChL case ended up winning two awards in the Global Chemical Leasing Awards organized by UNIDO including Bronze during 2014 Global ChL Award and Gold during the 2018 Global ChL Award